Add to Cart

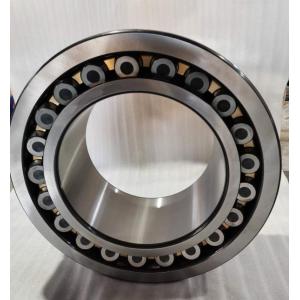

Cone crusher wear and spare parts slewing bearing

Our four point contact ball slewing bearing is made up of two seat rings. In this slewing bearing, the balls contact with the circular raceway at four points. The bearing can support axial force, radial force and resultant moment simultaneously.

Our four point contact ball slewing bearings are compact in design and light in weight. They can be applied in slewing conveyors, welding manipulators, middle or small sized cranes and excavators, etc.

| Type | Single row four point contact ball slewing bearing Double row crossed cylindrical roller slewing bearings Double row ball slewing bearings Wind power bearings Non-standard customized slewing bearing with inner/ outer gear |

| Rollng elements | Steel ball / Cylinder Roller |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin, Mounting holes, Inner ring, grease fitting, load plug, seals, roller, spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness | 229-269HB/Customized |

| Gear type | No gear, Internal gear, External gear |

| Certificate | SGS, ISO9001 |

Application area | Ladle turret, Stacker crane, Bucket wheel machine, Solar heliostat Tracking System, port crane, Cabling machine, tower crane, offshore platform, ferris wheel, Palletizing robot, Rotary metallurgical furnace, can packing machine, Wind blade transporter, shield tunneling machine, tube push bench, excavator |

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.

Aftersales service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.