Add to Cart

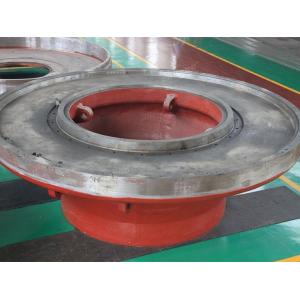

20-120T Customized grinding table High hardness anti-cracking wear resistant

Product introduction

Grinding table is a core part of vertical mill. We supplies customized service according to customers’ requirements. Besides, We obtains good reputations on grinding roller casting, finish machining and bead welding service.

Advantage

1. High hardness, anti-cracking and wear resistant

2. Arc air gouging technology is applied by ZTIC during finishing, making sure steel castings good appearance quality.

3. ZTIC promise: will do inspections before delivery to make sure each produced grinding roller is qualified, and refuse any inferior and defective products to be delivered.

Production Process

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

Dimensional check supported with a “as-built“ sketch;

Record of the heat treatment chart;

Standard&certificate:ASTM,BS,DIN,JIS and so on; ISO 9001:2000;BV,CCS,DNV,NK,RINA,KR and so on.

To ensure better cooperation, our factory provides the following service to the buyers:

1. OEM: As the special samples and drawings.

2. The small order is acceptable.

3. Comprenhive and professional after-sale services.

4. Advanced equipment and technology.