Add to Cart

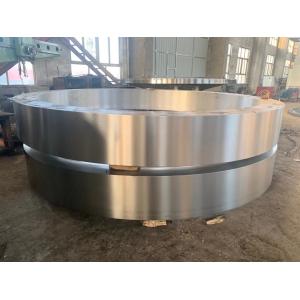

Rotary kiln spare parts 42CrMo large diameter casting steel forging ring rolling cement kiln tyres

Product Description

1. High strength, good durability

CHAENG uses ZG45 and ZG42CrMO material, which can guarantee the strength and toughness of rotary kiln tyre, so as to play a better supporting role.

2. Use advanced dual-medium quenching process

CHAENG adopts advanced two-medium quenching process to process uniformly every part of rotary kiln tyre, so that CHANEG rotary kiln tyre has high hardness and high toughness and good wear resistance, can adapt to a variety of harsh working environment.

3. Simple structure, easy for routine maintenance.

4. CHAENG can produce rotary kiln tyres of various specifications according to the customer's drawings.

The optimized technology and excellent quality can ensure that rotary kiln tyre produced by CHAENG matches well with the original rotary kiln equipment.

Cement rotary kiln tyre for cement plant

| |

(1) Mechanical Test Report

(2) Hardness Test Report

(3) Chemical Test Report

(4) Heat Treatment Record

(5) Magnetic Particle Examination Report

Rotary Kiln Tyre Quality assurance:

1. Chemical checking in the Qualified Lab

2. NDE after Rough Machining

3. Mechanical testing after Heat Treatment

4. Final NDE, Dimensions check